Nikko Ebonite Mfg.’s

Next Mission

Bringing the New Yet Old Material Ebonite From

Their Factory in Old Tokyo to the World!

Bringing the New Yet Old Material Ebonite From Their Factory in Old Tokyo to the World! Nikko Ebonite Mfg.’s Next Mission

Have you heard of the material ebonite?

Ebonite is a hard and lustrous synthetic rubber produced by adding sulfur to natural rubber and heating it. It is called ebonite because it resembles ebony in appearance. Because of its high insulation, chemical resistance, low thermal conductivity, and ease of processing, it was once used in a variety of applications, including electrical switches, joysticks, bowling balls, and electrical insulation components.

Today, plastics are easier to process, and, as a result, the number of products made with ebonite has gradually decreased. Today, there are only a few companies around the world that manufacture ebonite.

Continuing Operations Amid Declining Demand by Taking Advantage of Strong Technological Capabilities

One such company is Nikko Ebonite Mfg., which is apparently working to develop sales channels by developing and marketing products using ebonite. We visited their factory and had the opportunity to see their manufacturing process in action.

Located in Arakawa-ku, Tokyo, Nikko Ebonite Mfg. was established in 1952 by Katsuzo Endo, the grandfather of the current CEO Tomohisa Endo. The old wooden roofs and pillars in the factory give a sense of the company’s history.

While demand for ebonite has gradually declined and ebonite manufacturers have continued to shut down, Nikko Ebonite Mfg. has been able to continue its operations thanks to its advanced technological capabilities. When natural rubber and sulfur are mixed and heated, they turn into hard, stiff rubber. In order to produce high quality ebonite, Nikko Ebonite Mfg. uses high purity natural rubber and mixes sulfur in a unique ratio.

This photograph shows plates of ebonite made by kneading the materials and rolling them out.

These plates are heated and formed to create ebonite rods. Ebonite as a material is delivered in this rod form. These ebonite rods are made in various shapes and lengths to meet customers’ needs. Seeing the still warm, soft ebonite rods cut by hand was like watching candy artisans at work.

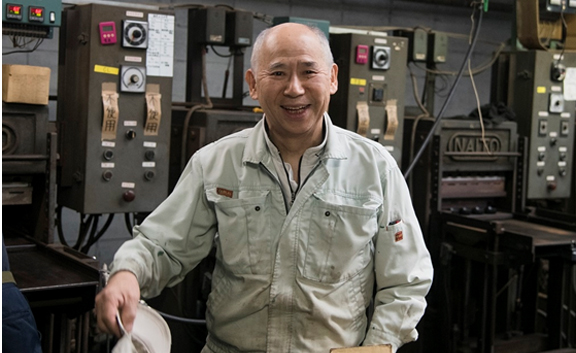

Next, we were shown the area where presses are used to mold various shapes with dies. This room is home to elegant presses that have been in use since the company’s founding as well as state-of-the-art processing machines. A variety of ebonite items are processed here.

Casters are one example of the items made using these presses. Ebonite, which offers excellent oil and load resistance, is used in the center of casters. Other presses were being used to make mouthpieces for woodwind instruments. Ebonite has long been used for mouthpieces. It is popular for its unique texture when placed in the musician’s mouth and the high-quality sound it affords.

Tradition and Innovation with Old-Fashioned Presses and State-Of-The-Art Processing Machines

In front of a state-of-the-art machine, the shaft of a fountain pen was being machined. Ebonite fountain pens are apparently popular among fountain pen enthusiasts because of their warmth and high machining accuracy.

The sight of a young artisan in their twenties working in front of a state-of-the-art machine while the chairman (and former president) continues to teach artisans truly feels like a fusion of the old and new.

Originally, Nikko Ebonite Mfg. only produced the raw material ebonite. But when sales fell sharply after the financial crisis of 2008, Endo felt a sense of urgency about the company’s situation and looked for a way to develop, process, and market final products themselves. In addition to fountain pens, they experimented with various products such as belt buckles and guitar picks. Of these, the fountain pen was the most promising.

Located about two doors away from the factory is Eboya, a shop that sells fountain pens and other ebonite products directly to customers.

Eboya, a Shop Exploring New Avenues for Ebonite

The shop has ballpoint pens and fountain pens available in various sizes, with colorful marble patterns and bamboo-like shapes. Visitors to the shop are inevitably captivated by their elegant colors and luster. The pens have a graceful warmth to them when held, and it is no surprise that fountain pen enthusiasts love ebonite shafts.

These pens begin with black ebonite. Nikko Ebonite Mfg. says it was initially quite difficult to produce the beautiful colors now available. Since each marble pattern is unique, customers can also enjoy choosing their very own one-of-a-kind pen. Today, the company is working to expand their sales channels to include Eboya, their own online shop, and special events at well-known department stores and stationary stores.

Ebonite offers a completely different warmth and elegance from ordinary plastic. CEO Endo participates in the Monozukuri Tours and Experience Events organized by Arakawa Ward and actively accepts factory tours in order to educate as many people as possible on the wonderful qualities of ebonite. This also provides opportunities for young entrepreneurs and business successors of SMEs to meet and interact, thereby helping to deepen the connections among SMEs and introduce their own and other SME products to the world.

The Arakawa Industrial Exhibition is another example of such an event. At this event, various companies share their own unique products made in Arakawa Ward leveraging technologies with consumers to develop stronger awareness.

We also visited the event, and it seemed to be a great success with customers looking through the physical products made by the technologically capable Nikko Ebonite Mfg. factory.

After visiting the factory and shop, we were curious if any other products could be made with ebonite.

Endo says that he would also like to focus on selling both original ebonite products and ebonite as a material overseas. We hope to see ebonite once again be used in various products and garner attention around the world.